What We Do

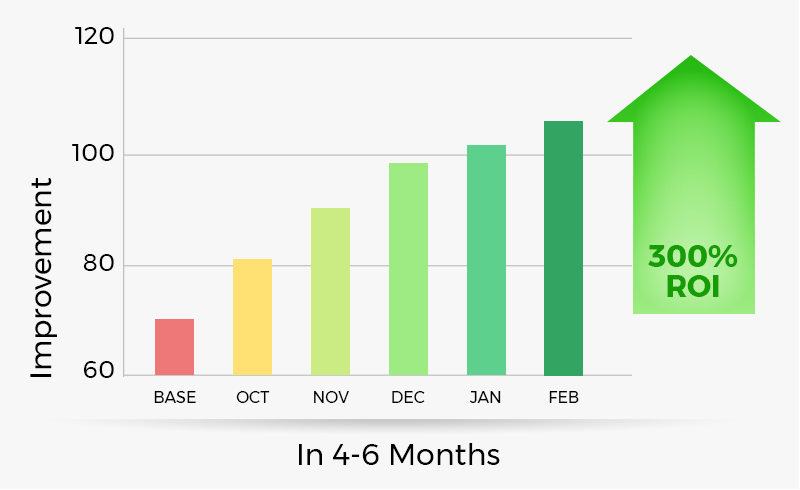

ABS specialises in the implementation of business performance improvement programs which deliver quantum leaps of improvement in profitability and growth. We offer Business Performance Consulting to help our clients achieve outcomes that are aligned to their business goals. Through ABS, measurable and sustainable results achieved are typically a 300% return on investment in the first year, together with value added improvements in customer service and quality levels.

Reset During the New Normal

Refocus Reset Restart

Our Expectation

from our analysis of +500 companies We believe even in the best managed companies, total resource utilization is only 50% – 60% Read More

How to Define it & Capitalize On It?

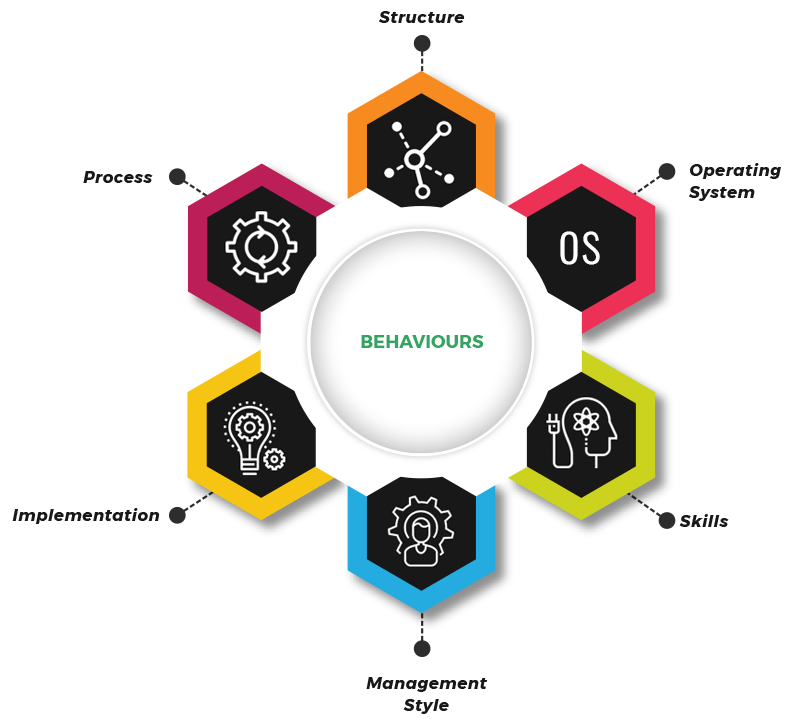

ABS strives to accelerate business profitability and performance through organisational behavior transformation. Through our services, we assess and carry out improvements in target areas for key improvement within a competitive setting. ABS consultants have applied proactive improvements programs in more than 500 of the most successful companies in the world.  The key to our success is in our ability to transfer the skills, know-how and OWNERSHIP to the organization and to implement the right BEHAVIOURS which will then be able to drive sustained results.

The key to our success is in our ability to transfer the skills, know-how and OWNERSHIP to the organization and to implement the right BEHAVIOURS which will then be able to drive sustained results.

OUR APPROACH

- Sales activity by 25-30%

- Cost to serve by 20-25%

- Inventory by 20-25%

- Procurement by 10-15%

- Maintenance by 35-40%

- Productivity by 25-30%

- Utility costs by 10-15%

- Added value services 20-25%

- Operating costs by 20%-25%

SELECTED PROJECTS RESULTS OVERVIEW

Fast Moving Consumer Goods Manufacturer

Read More

Port Operation

Read More

Latex Manufacturing

Read More

Plywood & Fibre Board Manufacturing

Read More

Consumer Products Marketing

Read More

Fast Moving Consumer Goods Manufacturing Logistics

Read More

Fast Moving Consumer Goods Logistics

Read More

General Insurance Company

Read More

Pharmaceuticals

Read More

Catheter Manufacturing

Read More

Quarry Operations

Read More

Marble & Granite Tile Manufacturer

Read More

Fast Moving Consumer Goods Manufacturer

Quality

Production Improvement Program

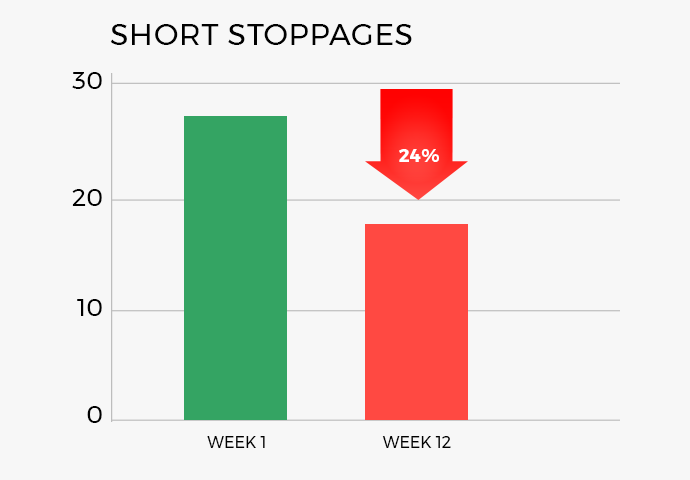

SHORT STOPPAGES REDUCED 24%

- Rejects reduced by 10%

- Throughput/ Productivity improved

- Implemented a short-stoppages management system “ACE”

- Developed an ongoing action orientated FMEA skills flexibility training program.

- Re-defined the machine cleaning & brand change procedures.

- Designed supervisory control tools to improve active supervision.

Port Operation

Result Driven Transformation

- Management Development

- Process / Procedure Enhancement

- Port Performance Management

Operating Cost Reduction

- Reduction in contractor costs

- Overtime improvement

- Added value services – Maintenance / Security / Safety

- Improved Equipment / Asset utilisation.

- Fleet Improvement

Revenue Improvement

- Developed additional revenue streams

- Increased sales activity

- Customer / market management system.

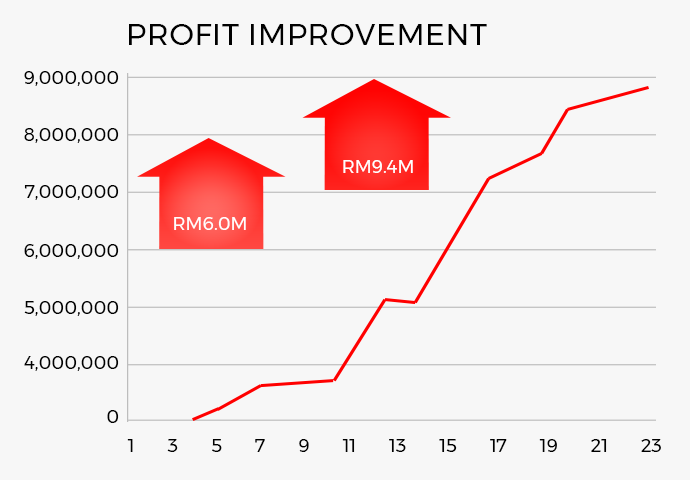

* An additional RM3.4M of improvements has been defined for delivery over the next 12 months

* An additional RM3.4M of improvements has been defined for delivery over the next 12 months Latex Manufacturing

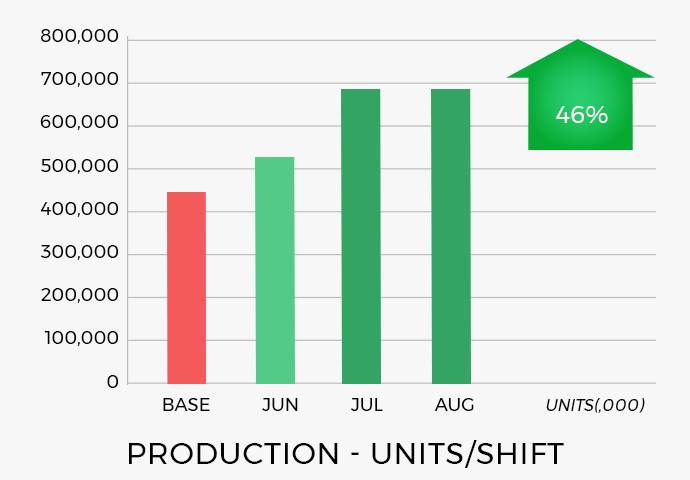

Throughput – Line Balancing

Health Care Industry

SHORT STOPPAGES REDUCED 24%

- Systems to manage operations, quality & customer services

- Installed total integrated quality activity at packaging area

- Skills development of workers

- Increased output by 46%

- Cost Reduction on utilities by 15%

- Productivity increase 25%.

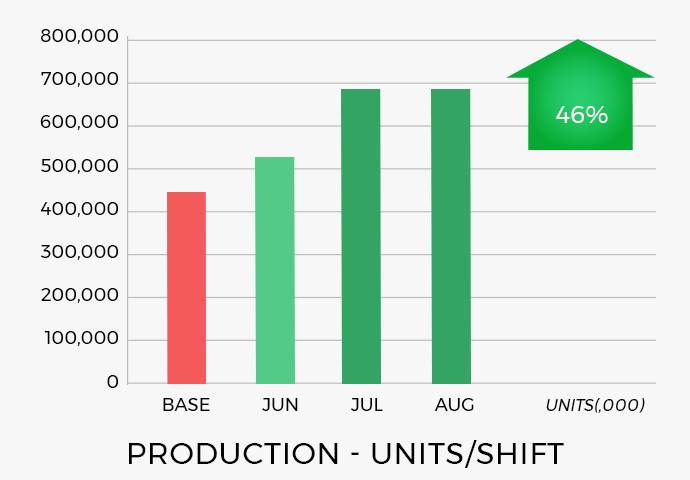

Latex Manufacturing

Throughput – Line Balancing

Health Care Industry

SHORT STOPPAGES REDUCED 24%

- Systems to manage operations, quality & customer services

- Installed total integrated quality activity at packaging area

- Skills development of workers

- Increased output by 46%

- Cost Reduction on utilities by 15%

- Productivity increase 25%.

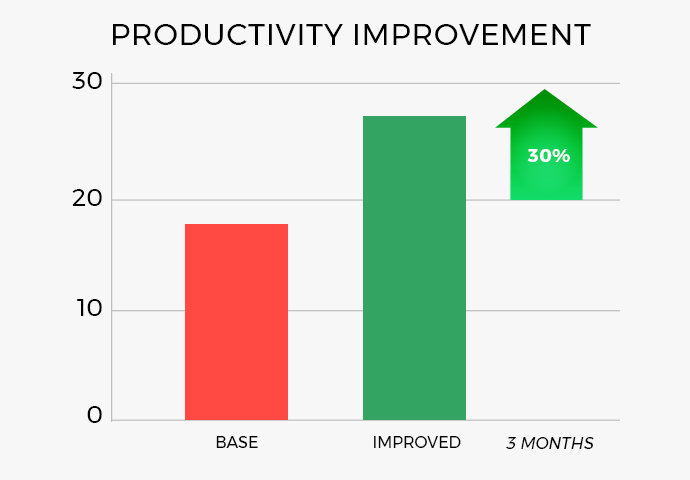

Plywood & Fibre Board Manufacturing

Productivity

- Improved line balancing through central control scheduling by 30%

- Central planning unit to improve forecasting and capacity planning

- Developed & conducted skills program to improved yield management by 15%

- Management training to improve active supervision

- Reduced unit cost by 18%

Consumer Product Marketing

Time To Market

PRODUCTIVITY IMPROVEMENT 44%

- Yield improvement 35%

- On-time delivery improved 27%

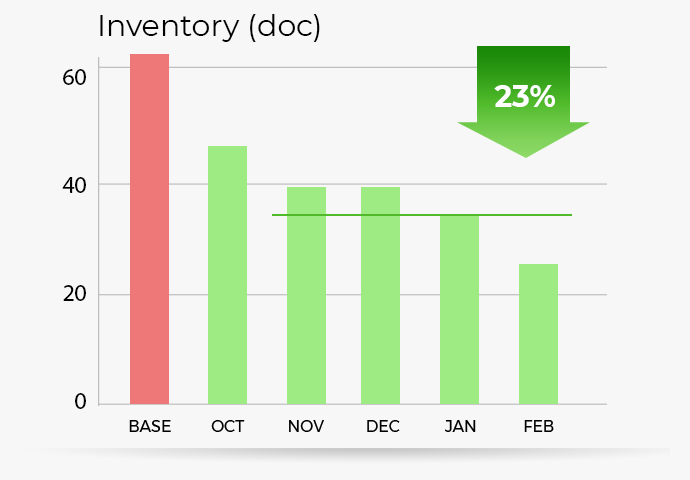

- Inventory MOC reduced by 23%

- Improved management systems

Fast Moving Consumer Manufacturing Logistics

Transport

- Improvement in route scheduling capacity loading of vehicles.

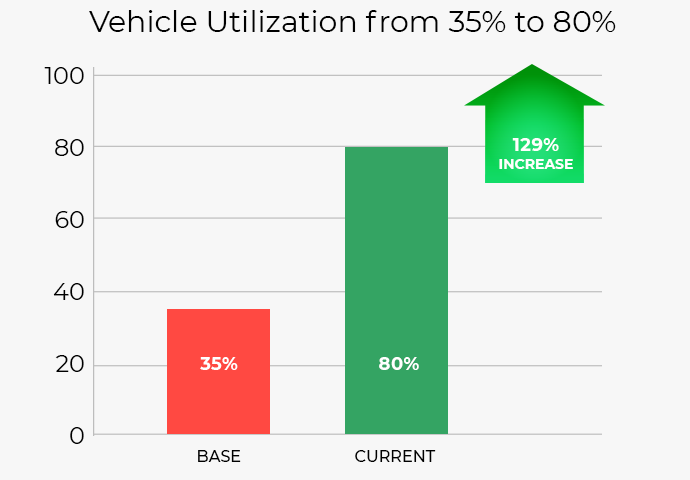

- Increased vehicle utilization from 35% to 80%

- Export container loading costs reduced by 47%

- Reduction in transport route cost by 20%

- Reduction of overtime for staff & customs by 20%

Total yearly transportation cost reduced by 28%

Fast Moving Consumer Goods Logistics

Logistics Costs

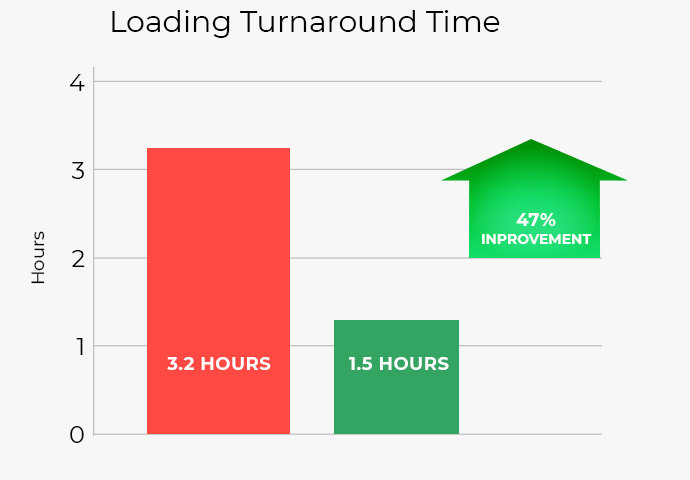

- Improvement in truck loading turnaround time from 3.2 hours to 1.5 hours.

- Improvement in truck departure cut-off

- Improvement in long term partners income (Individual truck operator by average of 27%)

- Annual transport cost reduction by 23%

General Insurance Company

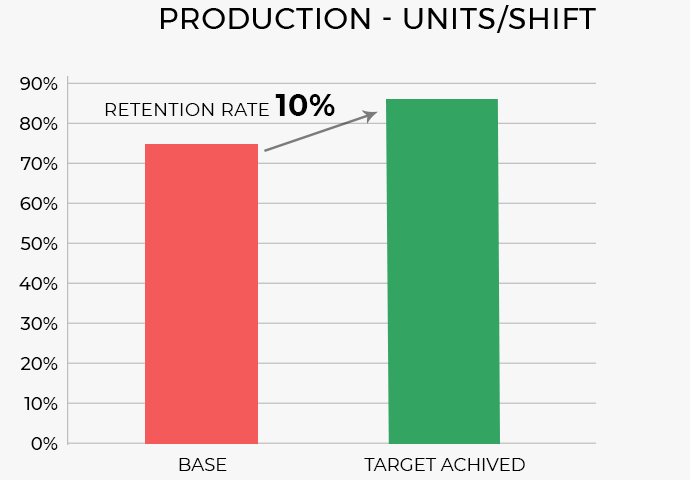

Sales Strategy Execution – Retention

New business / time & territory management GWP Increase by 25%

- Customized active selling skills program for distribution channels.

- Time & territory management controls for territory time planning to achieve targets call objective setting.

- Prospect funnel building, market intelligence controls

- Realign the roles of agency account managers

Retention management 10% drop-out premium reduction

- Short interval – retention management controls.

- Retention management skills for agency managers, account managers, branch support managers.

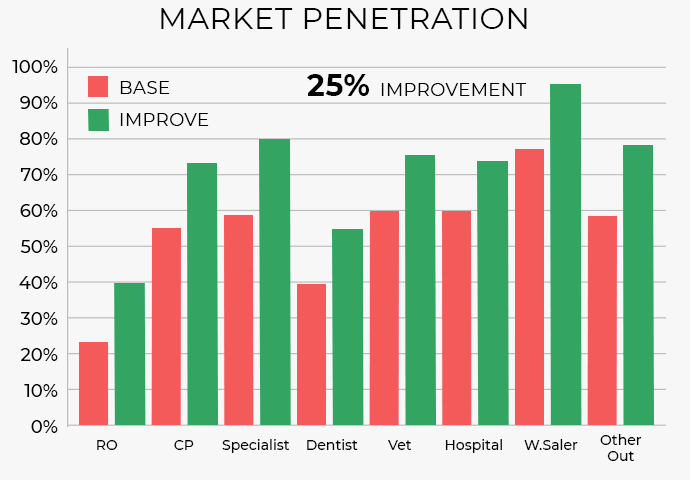

Pharmaceuticals

Sales Penetration

- Sales execution – to drive product & customer penetration by 25%.

- Dealer management operating systems – to improve dealer service levels and market reach.

- Direct selling & merchandising improvement to increase offtake

Annual Sales Increase By >20%

Other areas:

- Throughput & cycle time via central planning

- Logistics & procurement costs.

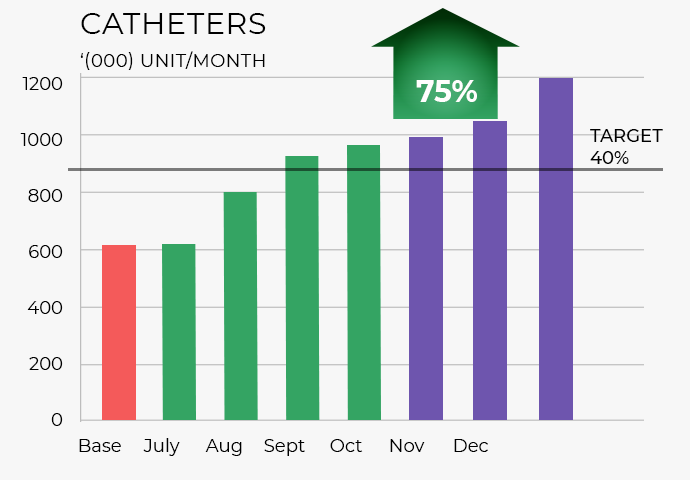

Catheter Manufacturing

Throughput

Catheters

Volume increase from 75% in 10 weeks and now it is at more than 100%

- Productivity improved by 50%

- Installed management operating systems for dipping, chlorination, packing & maintenance.

- Productivity improved by 20%

- Throughput improved by 7%

Energy

- Energy improvement program implemented

- Designed & installed methods (GSI) to reduce compressed air consumption by 70% at dipping area.

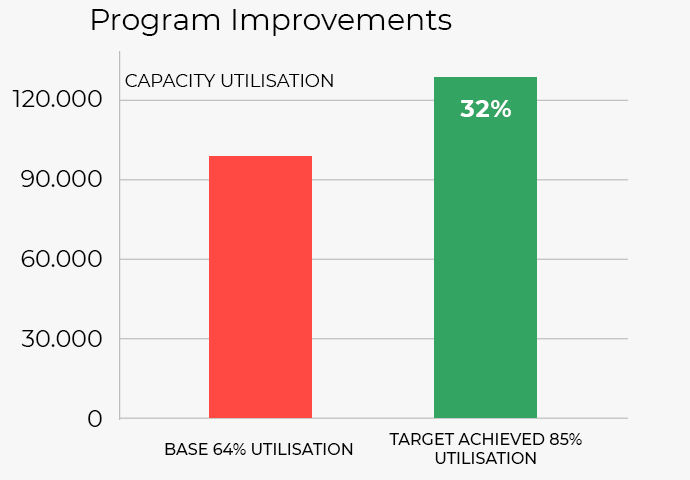

Quarry Operations

Increase plant capacity utilisation by 32% to reduce unit cost

- Demand Planning Management

- Short stoppage reduction.

- Central process/contractor control

- Maintenance management controls

- Repetitive failure reduction

Additional key result areas to increase revenue, cash-flow & profitability

- Sales strategy execution

- Accounts receivable control

- Product costing management

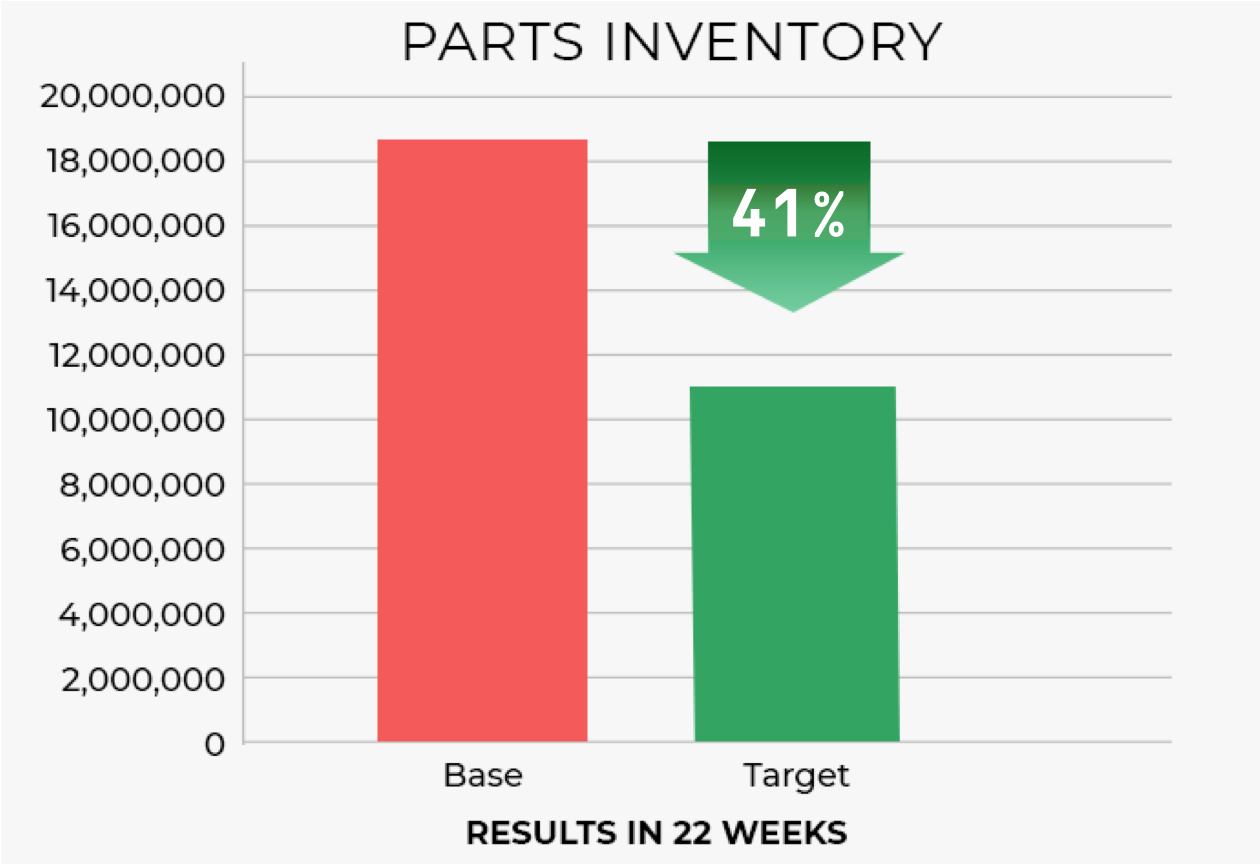

Marble & Granite Tile Manufacturer

Improvement

- Inventory reduced by 41%

- Price reduction by 8%- 15%

- Implemented procurement management best practices to ensure transparency & control

- Vendor assessment & management

- Competitive price review

- Supplier keeping stock review

- Parts standardization

- Re-order levels

- Local substitution

- Obsolete item prevention

(Other areas also include production, logistics, costing, product rationalization)